PROWLER System

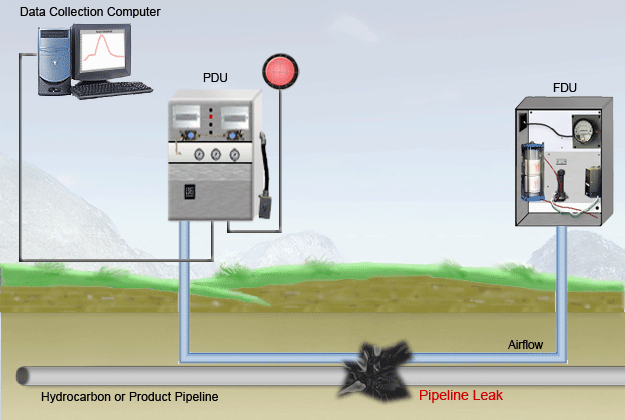

The PROWLER system is a unique system for detecting leaks of hydrocarbons and other hazardous materials from pipelines, underground storage tanks, fuel hydrant systems, and other applicable applications. The PROWLER system operates by the detection of vapors that migrate through the soil or other media from the leak source to the tubing, which captures a sample of the vapors. Essentially, the gas vapors diffuse into the tube to achieve a balanced vapor concentration (equilibrium) between the outside and the inside of the tube.

Since these vapors can emanate from either liquids or gasses, the system can monitor for either substance. The contents of the tube are periodically pumped and analyzed for changes from the ambient hydrocarbon backgrounds levels. Among the PROWLER system's unique features are its capability to operate in the presence of water (e.g. areas where the water table is high), its ability to detect very small leaks, the ability to analyze the background environment, and its ability to quickly and accurately locate the source of the leak.

Applications to date include gas and chemical pipelines, fuel hydrant systems, and underground storage tanks. Substances that have been monitored include benzene, pentane, ethylene, ethylene oxide, fuel oil, jet fuel (JP-4 and JP-8), sour gas (i.e., containing hydrogen sulfide), diesel fuel and gasoline.

Leak Determination

The Pump/Detection unit (PDU) does not make an exact determination, depending on the sensor, if the bump or peak is actually a leak from the pipeline. It only alarms when the newest recording varies from the Master recording. Because of the high sensitivity of the system, natural occurring sources of vapor may cause results similar to a leak signature. If it is determined to be a natural source, a new Master recording should be made to accommodate the changes.

The illustration shown below presents a preview of the software utilized in determining any anomaly that would lead to an investigation of what type of gas is being picked up by the system and if it is actually pipeline product. If further investigation is necessary, it is simply a matter of capturing the exhaust air output of the PDU during the period that the peak appears.

To do this, a two position valve is attached to the gas output connector on the PDU. The other side of the valve directs the output of the PROWLER to a standard gas sampling bag. As the PROWLER operates in the sampling step, the operator watches the output of the system until the point when the peak begins to appear. Immediately change the valve to direct the output air to the gas sampling bag. When the peak stops, return the valve to the original position. Now a captured sample of the vapor causing the peak is in the sampling bag. It may then be taken to a lab to determine the contents of the sample. Once identified, it is determined whether the source of the peak is a natural one or from the pipeline. If the gas is confirmed to be monitored product, the leak location would be investigated.

Installation

System installation can be a major cost factor for the system since the labor of trenching splicing, installing, backfilling, etc. often exceed the cost of the installed equipment. Typically, Nitor either subcontracts the installation work to a construction contractor or the construction contractor will server as the prime contractor for Nitor. Nitor can also act as a subcontractor supplying the equipment. Nitor performs system start-up and acceptance testing under either of the arrangements. Nitor training will consist of training for installation procedures, operations, and maintenance of the system.

Installation of the PROWLER system is critical for proper operation of the system, most problems occur with damage to the equipment and especially the sensor tubing itself. If proper care and attention are not given during the installation process, cuts or other damage to the sensor tube may cause results that will adversely affect the system operation. The leak-detection system is frequently installed as part of a much larger construction project, and often extends over several months , which makes it impractical and cost prohibitive for Nitor to keep personnel on-site at all times. Handling and storage of the equipment is crucial. For this reason, proper training of the installation contractor personnel will be critical to a successful and problem free installation.